Other Parts Discussed in Post: HDC3020 Relative humidity (RH) sensors are specialized sensors with an open cavity to measure water vapor present in the air. Relative humidity is a critical measurement, as humidity in the air can have a direct effect on system reliability (corrosion) or product longevity since humidity in a storage environment can have a direct impact on perishables.

One of the challenges with RH sensors is that its exposed sensing element ages over time. The constant exposure to moist air and volatile organic compounds in the environment, such as benzene or ethylene glycol depositing on the sensor material, will cause the sensor’s accuracy to drift out of its specification. This requires the system to be decommissioned for sensor replacement or calibration, which increases the total cost of ownership. In this article, I’ll discuss the accuracy and long-term drift of relative humidity sensors and how these parameters affect end-equipment performance and lifetimes. Read the application note, “How the HDC3020 Humidity Sensor Family Achieves The Industry's Lowest Drift” to learn more about implementing relative humidity sensors.

The highest reliability humidity sensors

|

Explore the HDC3020 family to optimize system efficiency and lifetime. |

Long-term drift and accuracy are some of the most important specifications for humidity sensors. In today’s humidity sensors, particularly capacitive-based sensors, an accuracy of 2% to 3% RH and a maximum of 3% to 4% RH are considered standard. This accuracy is what’s known as time-zero accuracy – before the sensor is put into actual use in the field – and excludes long-term drift.

The long-term drift for a capacitive-based sensor is typically around 0.25% to 0.5% RH per year. Even though this drift is quite small compared to resistive-based sensors (approximately 1% RH per year), it still amounts to a 5% RH shift over 10 years and becomes a significant source of error, affecting equipment such as appliances or automobiles that are built to run for longer than 10 years.

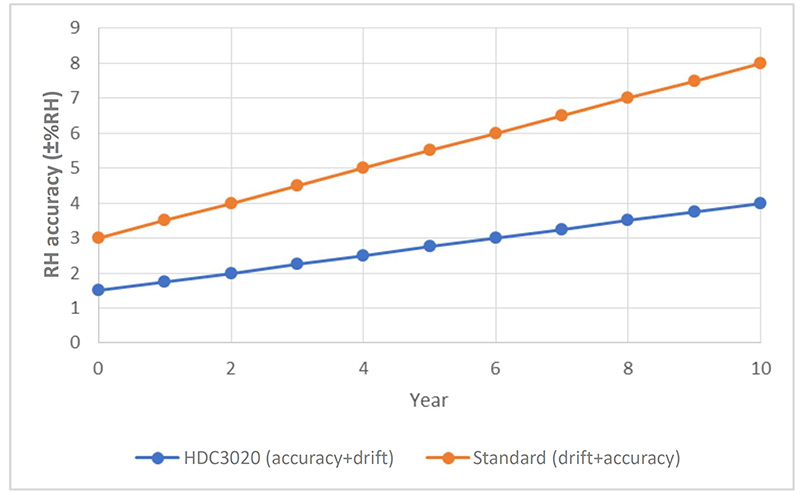

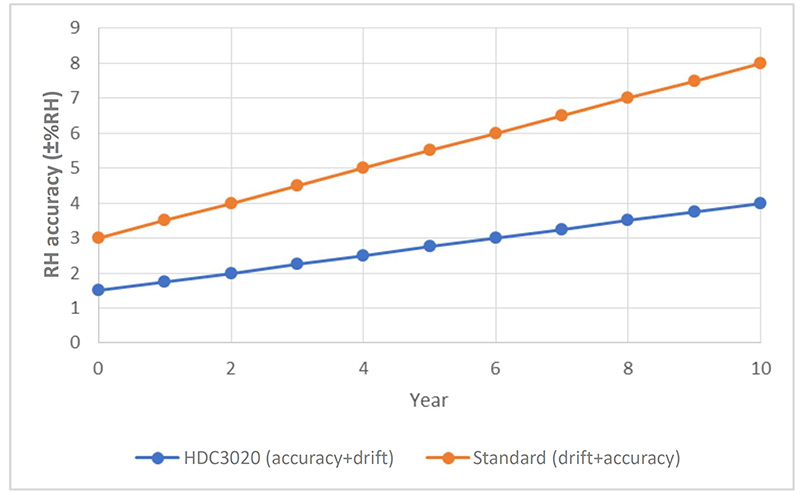

Figure 1 shows how accuracy and long-term drift can add up to 8% RH over 10 years. Using a refrigerator as an example, if drift causes an erroneous high-humidity reading, the compressor will turn on unnecessarily, resulting in less efficient operation, not to mention shortening the life of the compressor.

Figure 1: Humidity sensor accuracy with long-term drift

Humidity accuracy is also becoming more important in cold-chain applications such as perishable food, life science and pharmaceutical product storage and transportation. Wireless battery-powered trackers and data loggers allow sensors to continuously record temperature and humidity information of food shipments, in addition to horticulture and raw material powders. The loggers predict product longevity, and therefore need to be highly reliable and have accuracy traceable to the National Institute of Standards and Technology (NIST) measurement standards, while complying with the strict International Organization for Standardization (ISO) and International Electrotechnical Commission (IEC) 17025 regulation.

Power consumption is another important specification; in battery-powered applications, such as real time data loggers and environmental sensors, power consumption can mean the difference between using a larger, more expensive battery versus a smaller one that can help reduce cost. Low power consumption enables battery-powered applications to run longer, but accuracy over time becomes more critical, requiring potential calibration if accuracy shifts.

TI designed the HDC3020 RH sensor to enable longer system lifetimes while reducing power consumption. Its architecture offers accuracy across the full supply voltage for temperature and humidity: 1.5% RH typical and 2% RH maximum with a long-term drift of less than 0.21% RH per year. These parameters help extend the useful life of appliances and other types of systems, reducing long-term errors by as much as 50% to from 8% to 4% RH after 10 years, as exemplified in Figure 1.

The HDC3020 offers integrated drift correction technology to reduce drift caused by natural aging, environmental stress or interactions with contaminants. Preliminary performance of this technology can be evaluated using the HDC3020 EVM. For more information on environmental stress, read the white paper: 85°C/85% accelerated life test impact on polymer-based relative humidity sensors.

The HDC3020 also integrates a highly accurate 0.1°C (typical) and 0.4°C (maximum) temperature sensor with ultra-low power consumption. Both humidity and temperature are NIST-traceable, tested to standards in accordance with ISO 9001:2015 procedures according to NIST and in compliance with ISO and IEC 17025 policies. Removable tape and IP67 permanent filter cover options allow printed circuit board wash and conformal coating and protection from dust and water in harsh conditions, respectively.

Conclusion

When choosing a humidity sensor, you should consider not only accuracy but also long-term drift and environmental factors, as the exposed open cavity on a humidity sensor will accelerate sensor aging. NIST traceability for temperature and humidity is a good way to provide accuracy when a system is first released, but it does not account for other aspects such as sensor drift from aging or contamination, necessitating minimal long-term drift and drift correction to maintain accuracy over a sensor’s lifetime without recalibration. Choosing a highly reliable sensor directly translates to higher performing and more reliable products.