Have you ever woken up on a cold morning, stumbled over to your smart thermostat, and turned up the temperature by a degree or two just to get the heat started? I am sure most people can relate to having engaged in a similar type of interaction with their smart thermostat. Today’s smart thermostats give their users temperature adjustment granularity down to the degree. Have you ever wondered how this is possible?

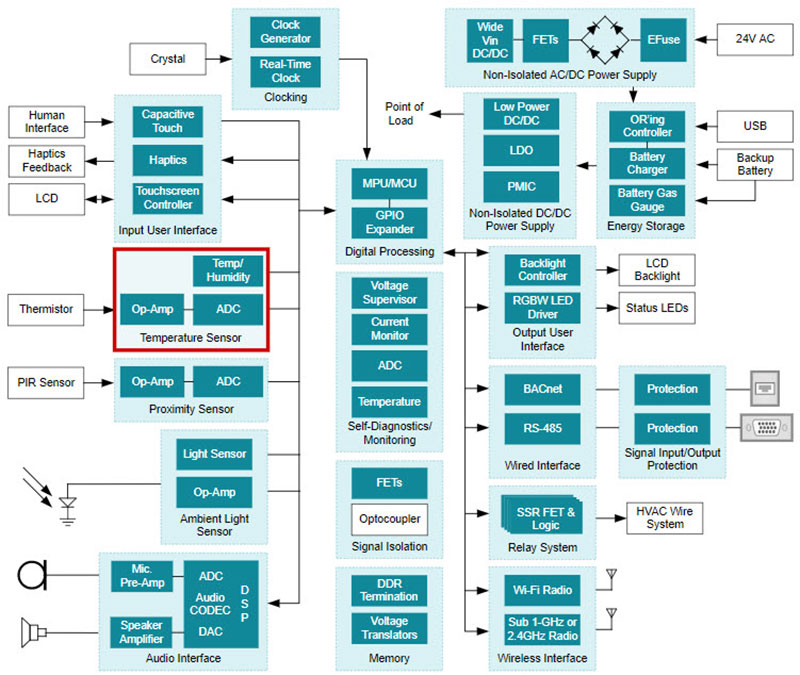

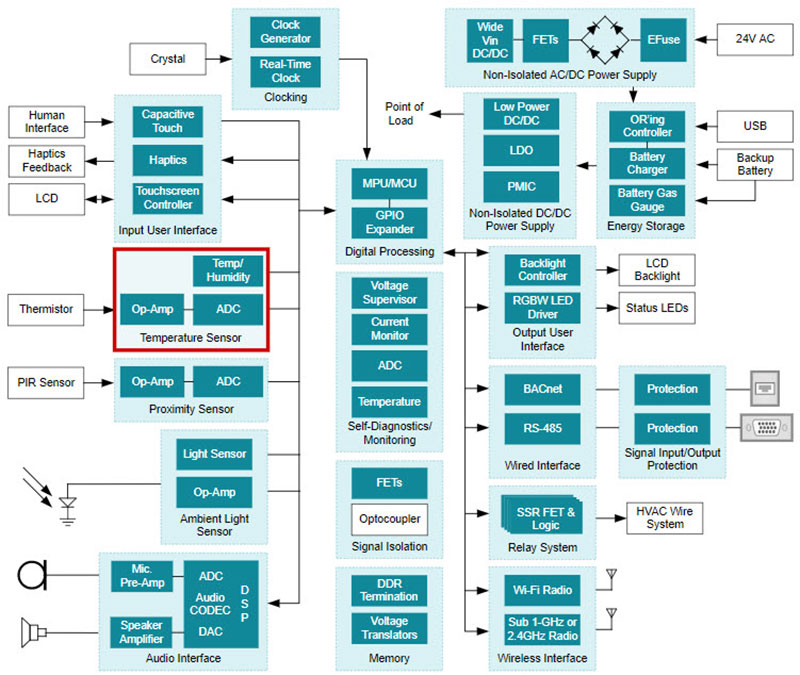

This type of temperature setting granularity is unheard of for analog thermostats. Analog thermostats use thermistors to measure ambient temperature. These thermistors have resistance tolerance ratings in the 0.5%-1% range which can equate to temperature accuracy from ±1-2°C at room temperature, meaning granular control of the temperature is not possible. Smart thermostats can provide per-degree granular adjustment capabilities by using digital temperature sensor integrated circuits that have sub-1°C accuracy levels in most cases. Figure 1 is a reference block diagram of a smart thermostat.

Figure 1: System block diagram of a smart thermostat

Integrated circuit-based temperature sensors are quickly becoming a key tool in a thermostat designer’s toolkit. One design challenge that designers face when implementing digital temperature sensors is interfacing the control and data input/output (I/O) interfaces with the thermostat’s main processor or controller I/O. In many cases, the digital temperature sensor’s I/Os are operating on voltage levels that may be different than the I/O voltage levels supported by the main processor, as a result of being developed in silicon process technologies optimized for temperature sensing.

In order to overcome the challenges posed by the I/O voltage level mismatch between the digital temperature sensor and the thermostat’s main processor, you can leverage voltage-level shifters or level-translation devices. Voltage-level shifters enable you to quickly and cost effectively level shift the control and data interfaces between the digital temperature sensor and the thermostat’s main processor, allowing the two devices to interoperate.

Level shifters are available in a wide variety of configurations, covering channel counts from 1 to 32 channels, with support for voltage levels from 0.65 V to 5.5 V. Level-shifter devices can level shift many common interface standards such as I2C, Serial Peripheral Interface, universal asynchronous receiver transmitter and general-purpose I/O (GPIO).

Let’s take a look at how simple level-shifting integrated circuits can help you implement level translation in smart thermostat designs.

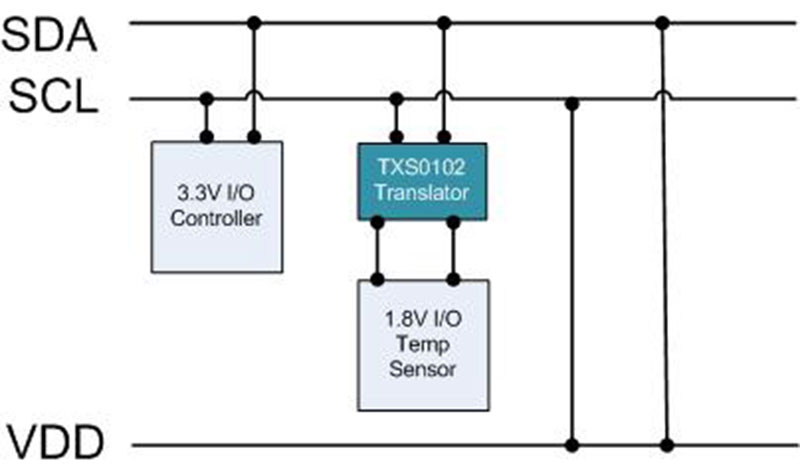

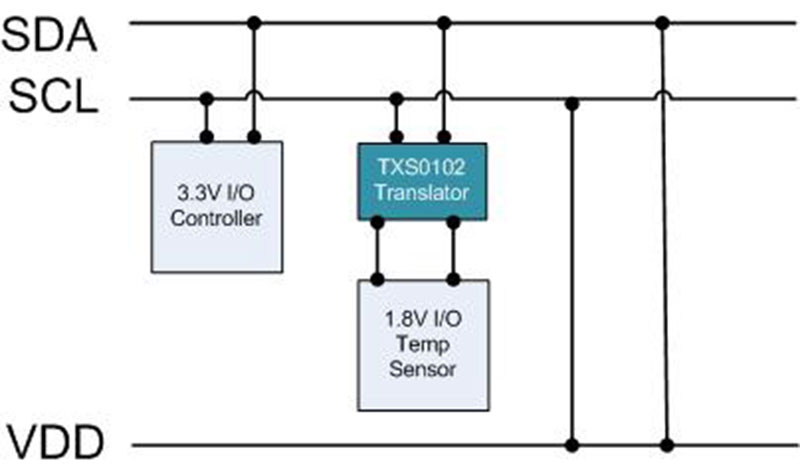

A common control interface between a digital temperature sensor and a thermostat’s microcontroller is I2C. I2C control buses are common standard open-drain control buses implemented in many systems. Often, the controller will operate on a common voltage node such as 3.3 V with a 3.3-V I2C control bus, while the digital temperature sensor will operate at a lower I/O voltage such as 1.8 V (or lower). In this case, an autodirectional level translator such as the TXS0102 can level shift between the 1.8-V I2C I/O of the temperature sensor and the 3.3-V I2C control bus, as shown in Figure 2.

Figure 2: I2C level-translation example using the TXS0102 with integrated pullup resistors

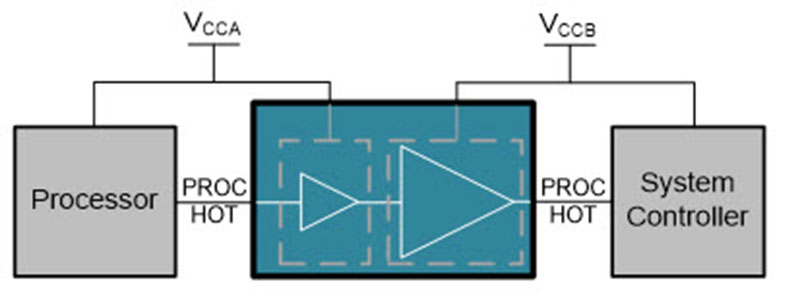

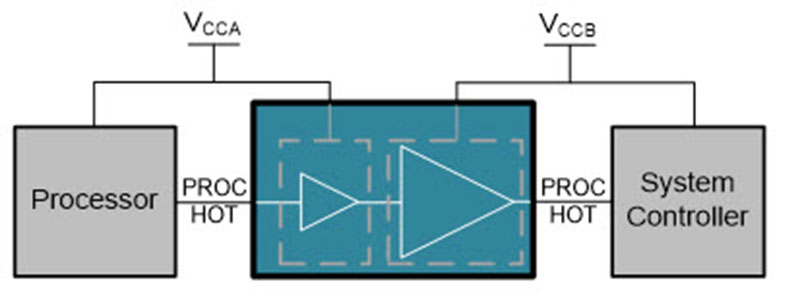

Another common approach to interface temperature sensors to a thermostat’s controller is to use the GPIO pins of the controller. The GPIOs can be easily level shifted using single or multichannel level-translation devices like TI’s SN74AXC2T45 dual-channel level translator, as shown in Figure 3.

Figure 3: Example of GPIO level translation using the SN74AXC2T45

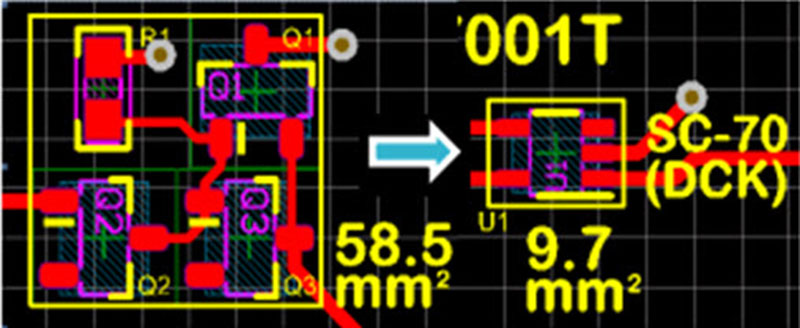

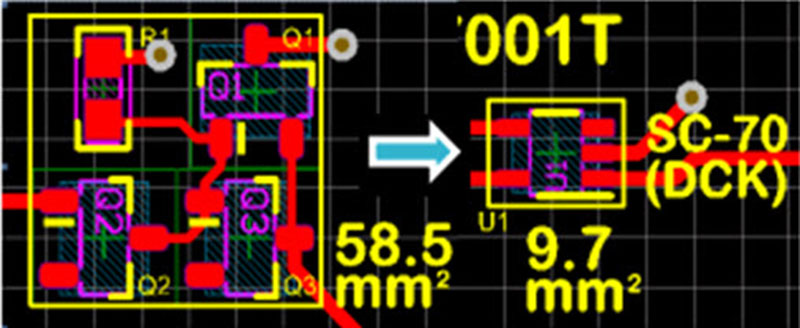

Some thermostat designers may consider discrete level-shifting solutions using components such as field-effect transistors (FETs) and resistor devices to implement very simple single- and dual-channel unidirectional level shifting. However, discrete approaches have specific drawbacks for thermostat designs; they use a considerable amount of board space, and the high leakage associated with components such as FETs means higher power consumption in standby mode.

For simple unidirectional level shifting and temperature sensor-to-processor interoperability, consider TI’s 2N7001T single-channel unidirectional level translator. A 2N7001T-based implementation consumes 80% less board area than comparable discrete solutions, while also providing considerably lower leakage, better signal performance and a much simpler implementation, for about the same solution cost as discrete implementations. Figure 4 compares a common discrete push-pull level-shifting implementation and an integrated implementation using the 2N7001T.

Figure 4: Size comparison between a discrete push-pull level translation (left) and the 2N7001T implementation (right)

As smart thermostat designs add even more intelligence and capabilities, level-translation solutions from Texas Instruments enable you to implement critical connectivity between key system components. For more information on level translation and smart thermostat design solutions, see TI’s level translation page as well as the smart thermostat solutions page.