Load Cell Product

Brake Pedal Load Cell with Special Mounting Plate

Load Cell Application

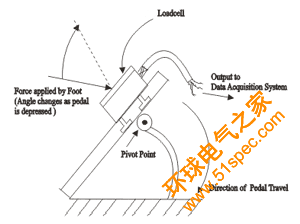

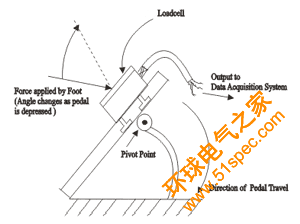

An aircraft manufacturer needs to measure the force a pilot must apply to the brake pedal to stop an airplane.

To do this, a load cell is affixed to the brake pedal's upper surface. A test technician then applies a force with his/her foot. Another load cell is sandwiched between the brake shoe and the drum.

The force applied at the pedal is compared to the force generated at the drum and to manufacturing tolerances to determine if adjustments need to be made. The hydraulic controls of the plane can then be adjusted to ensure that with a given pilot force, an appropriate force is generated at the brake pad that will allow the plane to brake safely.

The travel of the brake pedal creates issues that necessitated the development of a special load cell. As the pilot depresses the pedal, the angle at which the load is applied changes. This creates a different force component being transmitted to the load cell which, in turn, creates error as the load cell interprets this as a changing force. In addition, the pedal rolls toward the end of the stroke and amplifies this force component error.

Solution to Load Cell Application

Honeywell designed a load cell with a large, flat loading surface (3 inch diameter). The load cell gives the same output (+/- 1%) no matter where the force is applied across this surface.

The flat loading surface increases similarity with the original pedal surface. A set of tapped holes on the underside allows it to be firmly attached to the pedal.

By minimizing the error due to off-axis loads, this load cell allowed this customer to more accurately calibrate and certify the braking system of its plane.